Research on the aircraft structures and advanced composite materials

JAXA Supercomputer System Annual Report April 2018-March 2019

Report Number: R18EA1601

Subject Category: Aeronautical Technology

- Responsible Representative: Toshiya Nakamura, Aeronautical Directorate, Structure and Advanced Composite Technology Reasearch Unit

- Contact Information: Yuichiro Aoki(aoki.yuichiro@jaxa.jp)

- Members: Akinori Yoshimura, Masaya Ebina, Yuichiro Aoki, Toshiyuki Kasahara

Abstract

Application of the composite materials will contribute to improving the performance of aircraft and spacecraft components. JAXA conducts researches for overcoming weaknesses of current composite materials, clarifying unknown aspects such as fracture mechanisms, improving performance and enabling application to design technology.

Reference URL

Please refer to ‘Structural/composite materials technology | Science & Basic Tech. – Aeronautical Science and Basic Technology Research | Aeronautical Technology Directorate‘.

Reasons for using JSS2

We performed damage simulation of CFRP under impact loading in order to assess the design safety of CFRP structure. For precise simulation, each CFRP lamina must be modeled separately, and huge number of DoFs are needed. Application of the supercomputer system makes such high-computational-cost calculation possible.

Achievements of the Year

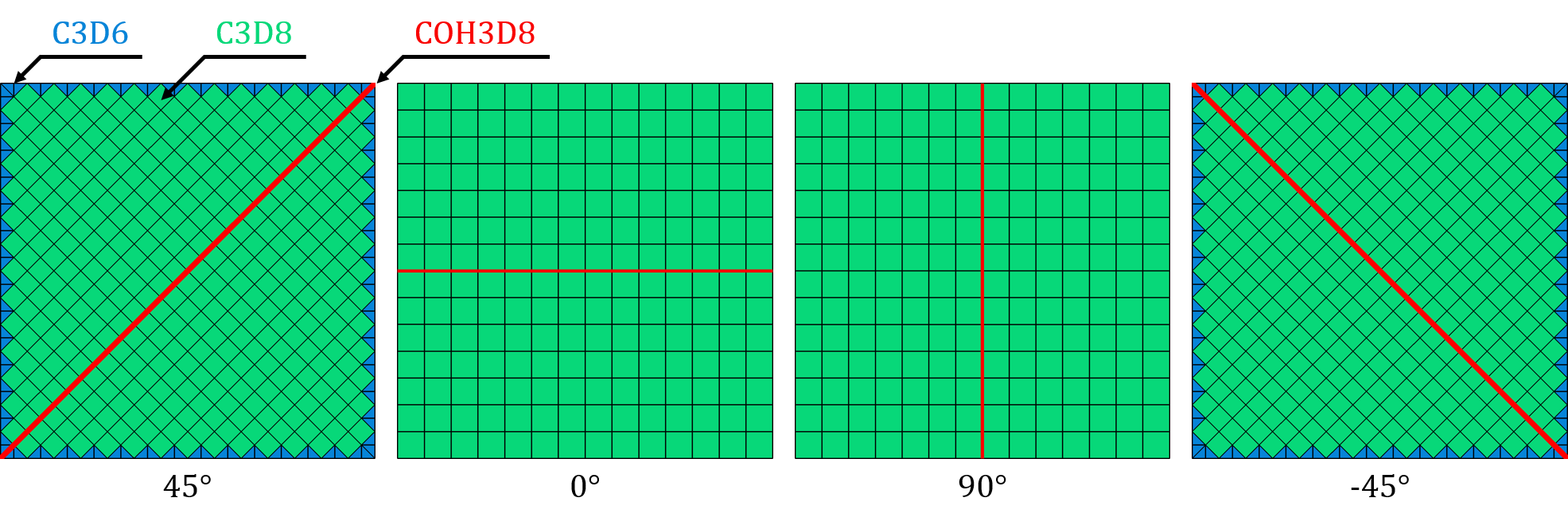

Precision of the low-velocity impact damage simulation for the CFRP laminate was improved by using multiscale calculatiuon method. Low-velocity impact tests were performed based on the ASTM D7136 standard, and damage was measured by non-destructive inspection (NDI). Simulation was performed using ABAQUS/Explicit 2016 on JSS2 system. Each ply of the CFRP laminate was modeled by one continuum shell element in the thickness direction. ECDM model was implemented using usersubroutine of ABAQUS.

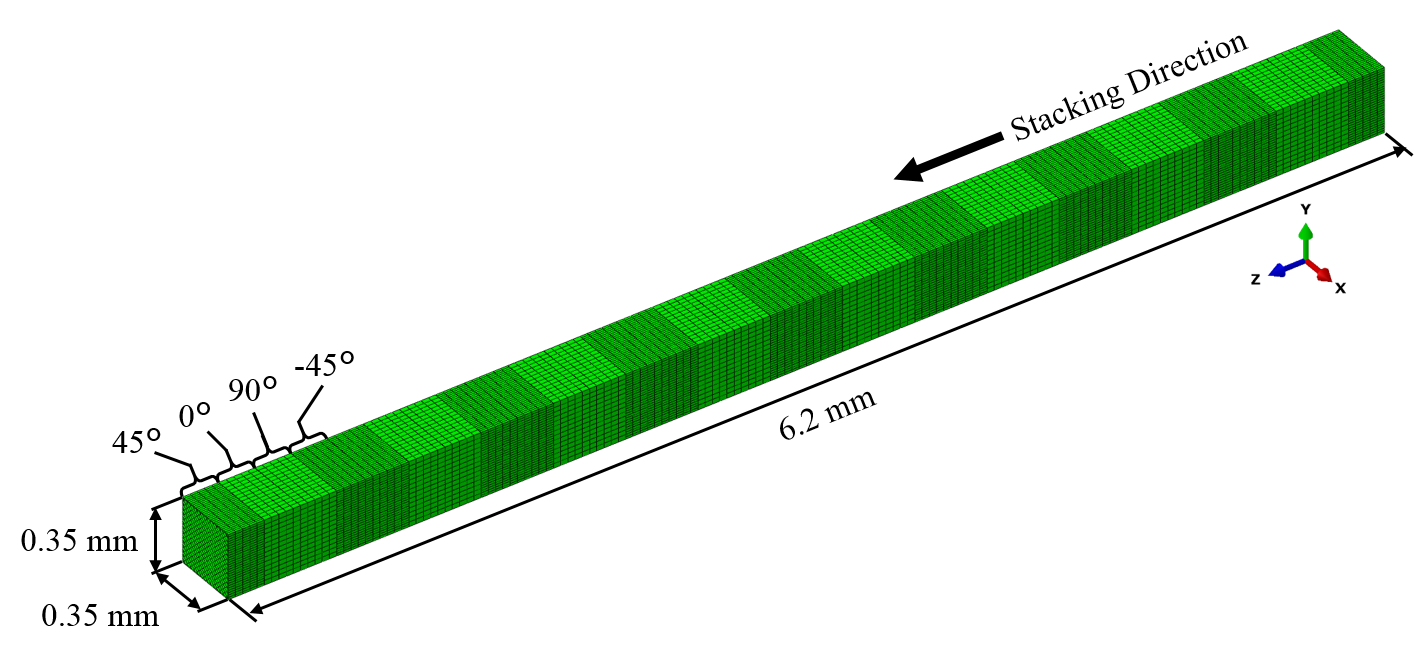

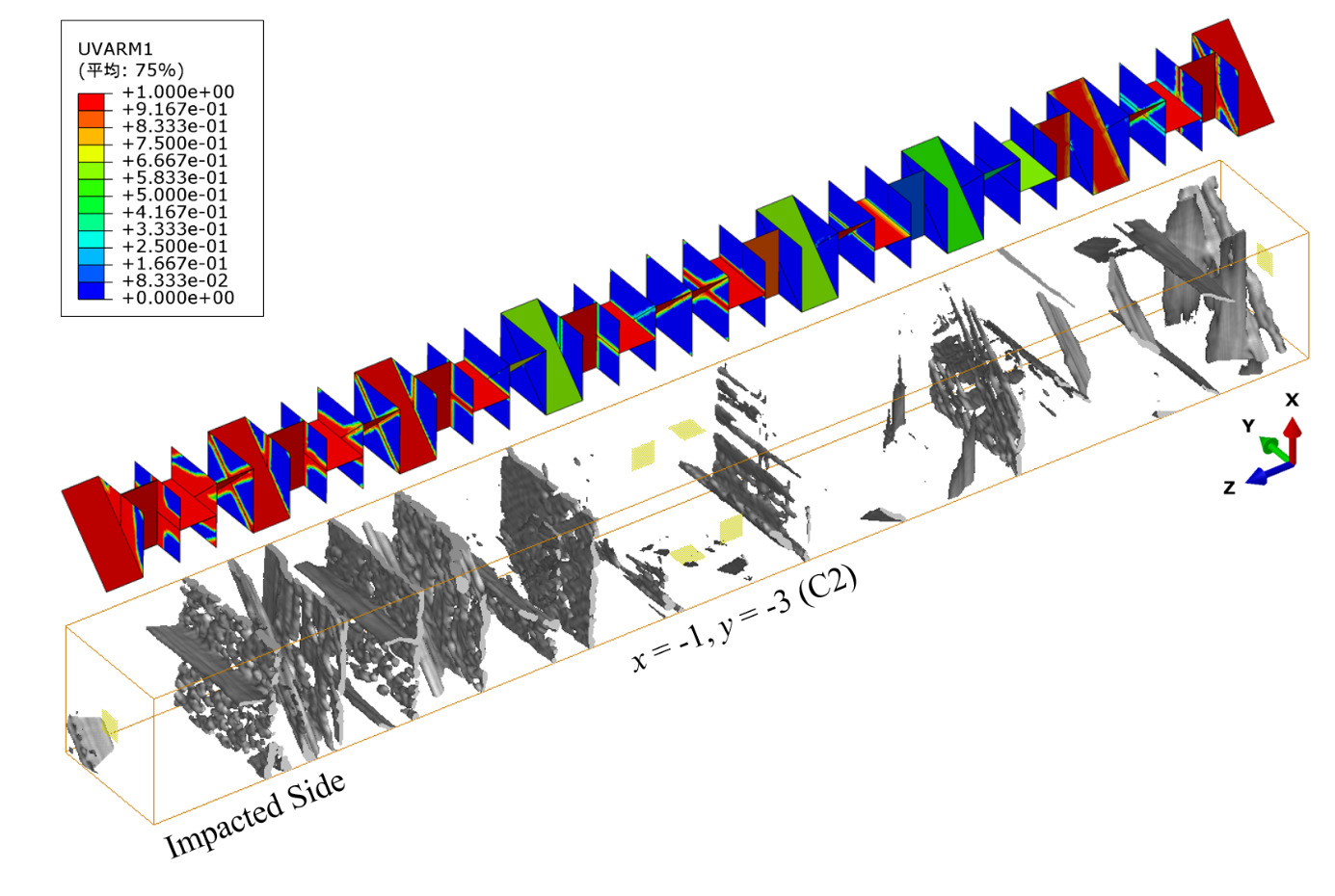

In the macroscopic model (Fig. 1), the CFRP laminate was modeled by one continuum shell element in the thickness direction. The damage was simulated by using ECDM model, which was developed in JAXA in the last year. Microscopic model consists of solid elements and cohesive elemtns (Figs. 2, 3). Macroscopic strain which was calculated in the macroscopic model was applied to the microscopic model, and microscopic damage can be predicted. Figure 4 compares the simulated damage and the damage mesasured by the micro-focus X-ray CT.

Publications

– Peer-reviewed papers

Masaya Ebina, Akinori Yoshimura, Kenichi Sakaue, Anthony M. Waas. “High fidelity simulation of low velocity impact behavior of CFRP laminate”, Composites Part A, 113, 166-179, 2018

– Oral Presentations

Masaya Ebina, Akinori Yoshimura, Kenichi Sakaue, Yuichiro Aoki, ‘Low Velocity Impact Simulation of CFRP Laminates Considering Microscopic Damage Interaction’, 33rd American Society for Composites Technical Conference, Sep. 2018, Seattle, WA, USA

Usage of JSS2

Computational Information

- Process Parallelization Methods: MPI

- Thread Parallelization Methods: Automatic Parallelization

- Number of Processes: 1 – 120

- Elapsed Time per Case: 20 Hour(s)

Resources Used

Fraction of Usage in Total Resources*1(%): 0.20

Details

Please refer to System Configuration of JSS2 for the system configuration and major specifications of JSS2.

| System Name | Amount of Core Time(core x hours) | Fraction of Usage*2(%) |

|---|---|---|

| SORA-MA | 0.00 | 0.00 |

| SORA-PP | 282,092.60 | 2.25 |

| SORA-LM | 0.00 | 0.00 |

| SORA-TPP | 0.00 | 0.00 |

| File System Name | Storage Assigned(GiB) | Fraction of Usage*2(%) |

|---|---|---|

| /home | 36.56 | 0.04 |

| /data | 49,193.72 | 0.87 |

| /ltmp | 7,486.98 | 0.64 |

| Archiver Name | Storage Used(TiB) | Fraction of Usage*2(%) |

|---|---|---|

| J-SPACE | 0.00 | 0.00 |

*1: Fraction of Usage in Total Resources: Weighted average of three resource types (Computing, File System, and Archiver).

*2: Fraction of Usage:Percentage of usage relative to each resource used in one year.

JAXA Supercomputer System Annual Report April 2018-March 2019