Challenges in 3D Modeling Visualization Technology

The Supercomputer Operation Center’s Visualization Team offers cutting-edge visualization technology to enable users to efficiently study the results of numerical simulations. Apart from utilizing existing visualization applications and devices, we continually explore fresh possibilities, striving to integrate innovative ideas into our visualization technology.

We are excited to introduce a groundbreaking visualization technology known as “3D Modeling Visualization Technology,” a project that has been in development for several years, harnessing the capabilities of a 3D printer.

The “3D modeling visualization technology” was created as a completely new visualization technology using 3D printers.

Numerical simulation is a technology employed to analyze physical phenomena within a three-dimensional space digitally recreated on a computer. Consequently, assessing calculation results in a three-dimensional format is more ideal than in two dimensions.

In recent years, the accessibility of 3D printers to the general public has enabled the creation of realistic 3D models representing numerical simulation results. The Visualization Team initiated the development of a technology for 3D modeling of calculation outcomes at an early stage and is currently addressing the challenges associated with 3D printing.

Initial Stage: Modeling of monochromatic shape model

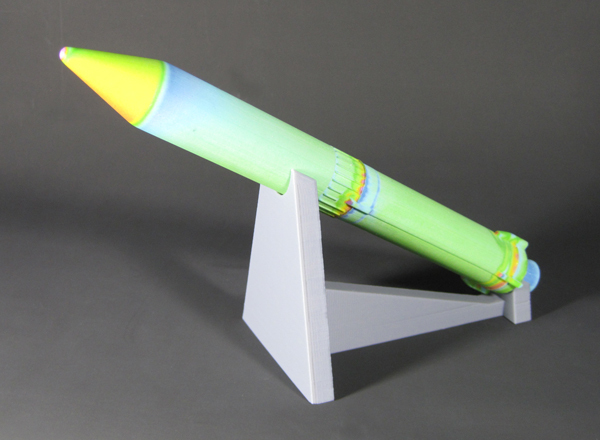

3D printers excel in reproducing CAD data, making them an ideal choice for manufacturing the airframe contours of aircraft and spacecraft.

To gain a better understanding of these intricate fuselage and rocket engine designs, we employed 3D printing technology. Nonetheless, the limitation of producing monochromatic prints prevented us from accurately representing the outcomes of our numerical simulations.

Aircraft Shape Print (monochromatic print)

Supersonic Aircraft Shape Print (monochromatic print)

LE-X Rocket Engine Shape Print (monochromatic print)

Second Stage: Realization of full-color printing

3D printers can be categorized into various types based on the materials they utilize.

During an exhibition where we showcased a monochromatic printed model, we learned about the existence of a 3D printer capable of producing full-color prints. Intrigued by its potential for visualization, we promptly conducted experiments to explore its applicability.

In the context of full-color printing, we encountered a challenge regarding the durability of the end product due to the use of plaster as the modeling material. To address this issue, we implemented measures such as slightly increasing the thickness for slender shapes, ultimately achieving the successful representation of the aircraft’s surface distribution.

Surface pressure of the VTOL ASKA (full-color print)

Iso-surface of buffet analysis of high angle attack airplane colored by pressure distribution

(full-color print)

Surface pressure of Epsilon Launch Vehicle (full-color print)

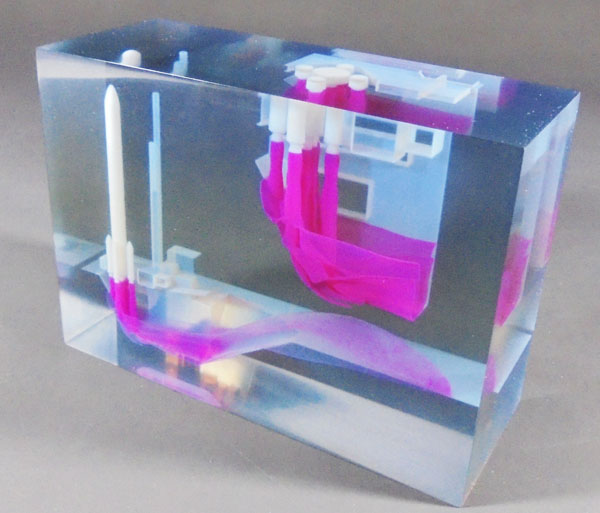

Latest: 3D visualization technology using transparent resin

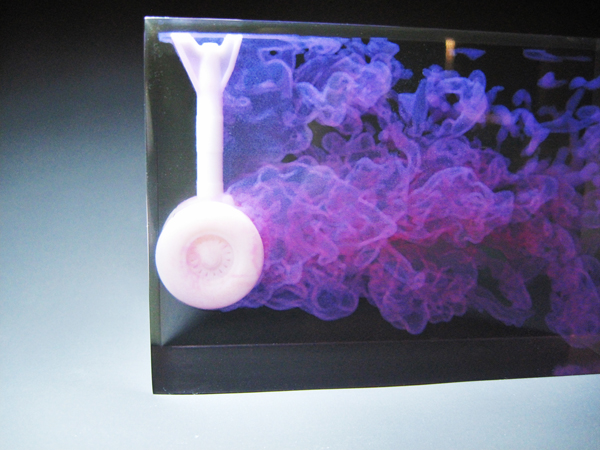

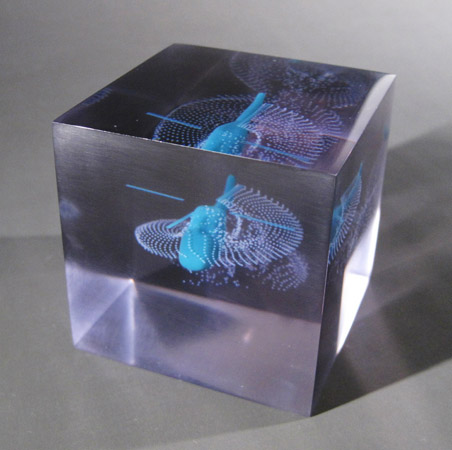

The latest 3D printers can utilize various molding materials, enabling us to now represent the desired “vortex-like flow created around the vehicle” by simultaneously printing both transparent and opaque resin.

Since the “three-dimensional representation of vortices away from the aircraft” has received high acclaim from researchers, our aim is to develop this technology into a “user-friendly visualization tool” that can be employed for “verifying calculation results” in the future. However, to achieve this, it is crucial to learn how to process vast data into data suitable for 3D printing and to master 3D design that considers the necessity of presenting the data as a three-dimensional object.

Additionally, there are concerns related to printing time and cost. The next step involves enhancing 3D visualization technology in line with the forthcoming advancements in 3D printing.

Liquid fuel atomization analysis model (transparent resin print)

Flow field around landing gear (transparent resin print)

Flow display from helicopter rotor (transparent resin print)

Analysis of the jet stream from the launch vehicle at the launch pad

(transparent resin print)

Launch-pad acoustic analysis of H3 launch vehicle (Transparent Resin Print)

Display of the vortex behind the HTV-R (Transparent Resin Print)

Buffet analysis of aircraft flying at a high angle of attack (transparent resin print)