Environment Conscious Aircraft Systems Research in Eco-wing Technology

JAXA Supercomputer System Annual Report April 2017-March 2018

Report Number: R17ETET15

Subject Category: Skills Acquisition System

- Responsible Representative: Yoshikazu Makino, Aeronautical Technology Directorate Next Generation Aeronautical Innovation Hub Center

- Contact Information: Dongyoun Kwak kwak.dongyoun@jaxa.jp

- Members: Hotaka Kobayashi, Yutaro Yamasaki, Dongyoun Kwak, Shihoko Endo, Hiroki Adachi, Shoya Ogino

Abstract

Innovative drag reduction technologies are investigated to reduce the fuel consumption for a conventional aircraft configuration. Aircraft noise prediction technologies and the conceptual design technologies are also developed for future aircraft which achieve low noise and high efficiency.

Reference URL

Please refer to 'Eco-wing technology | ECAT - Environment-Conscious Aircraft Technology Program | Aeronautical Technology Directorate'.

Reasons for using JSS2

CFD analysis are used for the understanding of aerodynamic characteristics and evaluation of the performance in the aircraft design phase. Huge calculation resources and costs were required for the high fidelity and quick response CFD analysis for the optimum aerodynamic design process on complex aircraft geometry. JSS2 can achieve those requirements, the cost and time are drastically saved on the CFD analysis.

Achievements of the Year

Drag reduction technologies and noise reduction technologies are investigated by cooperation with universities.

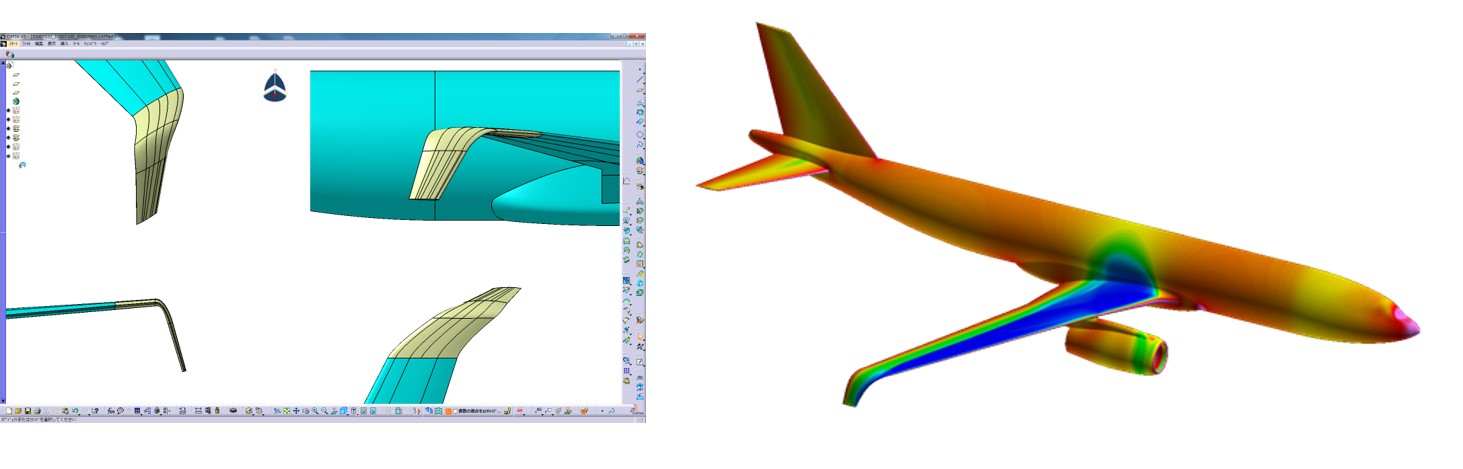

On the drag reduction technologies, two wingtip geometries were designed to reduce induced drag component using numerical analysis. A downward rakelet configuration, which is a wingtip configuration with a raked wingtip accompanied by a downward winglet section, can reduce the induced drag by reduce the interaction caused by trailing edge vortex, and reduce the wave drag by cotrolling the shock wave caused from the corner area of the winglet. The downward rakelets with a 105% span length achieve a drag reduction more than 3% compared with the baseline configuration(Fig.1). These benefits were validated from experimental data obtained by JAXA 2mx2m transonic wind tunnel campaign.

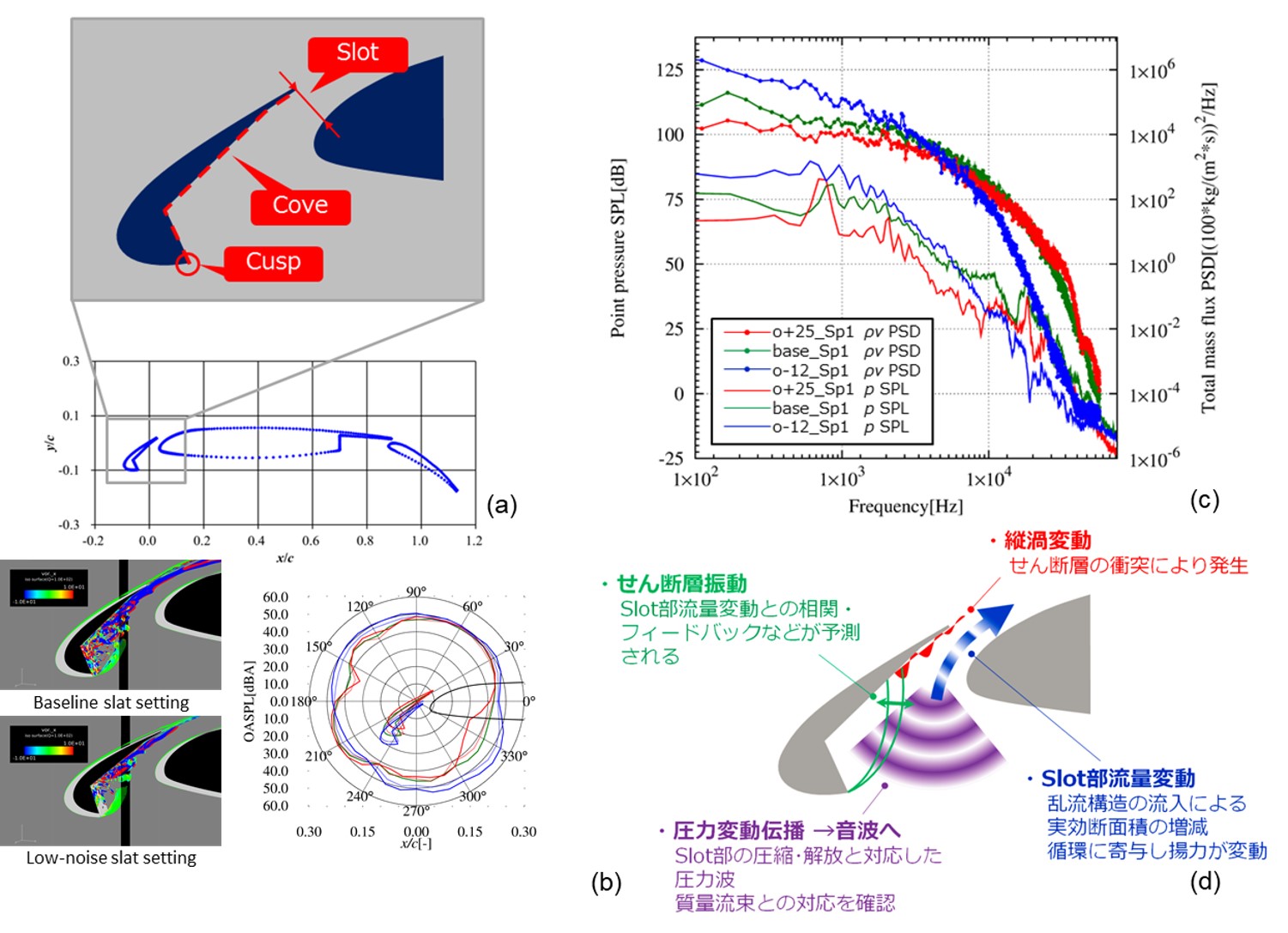

On the aircraft noise reduction technologies, a reduction method of airframe noise from leading-edge slat deployed at take-off/landing high-lift conditions by slat setting optimization has been investigated. An empirical noise evaluation parameter proposed for slat setting optimization using low cost steady RANS CFD has been validated with high-fildeity unsteady DDES CFD simulations. The noise generation/reduction mechanisms have been investigated by the detail comparison of flowfields and noise levels of baseline and evaluated configurations with slat settings varied and the design knowledge toward low-noise slat has been acquired (Fig.2).

Fig.2: Study on slat noise reduction by slat setting optimization and noise generation/reduction mechanisms: (a) Three-element high-lift airfoil, (b) Visualization of unsteady flowfields (Q-criterion colored by x-vorticity) and OASPL, (c) Comparison of PSDs of m

Publications

■ Non peer-reviewed papers

1) Yuhara, T., Kubota, K. and Rinoie, K., "Drag Divergence Characteristics of Winglets", AIAA SciTech 2018, AIAA Paper 2018-0046.

Usage of JSS2

Computational Information

- Process Parallelization Methods: MPI

- Thread Parallelization Methods: OpenMP

- Number of Processes: 15 - 50

- Elapsed Time per Case: 300.00 hours

Resources Used

Fraction of Usage in Total Resources*1(%): 0.18

Details

Please refer to System Configuration of JSS2 for the system configuration and major specifications of JSS2.

| System Name | Amount of Core Time(core x hours) | Fraction of Usage*2(%) |

|---|---|---|

| SORA-MA | 1,038,242.42 | 0.14 |

| SORA-PP | 14,889.15 | 0.19 |

| SORA-LM | 8.52 | 0.00 |

| SORA-TPP | 0.00 | 0.00 |

| File System Name | Storage Assigned(GiB) | Fraction of Usage*2(%) |

|---|---|---|

| /home | 889.49 | 0.62 |

| /data | 22,837.66 | 0.42 |

| /ltmp | 20,833.34 | 1.57 |

| Archiver Name | Storage Used(TiB) | Fraction of Usage*2(%) |

|---|---|---|

| J-SPACE | 62.92 | 2.71 |

*1: Fraction of Usage in Total Resources: Weighted average of three resource types (Computing, File System, and Archiver).

*2: Fraction of Usage:Percentage of usage relative to each resource used in one year.

JAXA Supercomputer System Annual Report April 2017-March 2018