Numerical calculation of Green engine (study of ultrahigh-temperature low NOx emission combustor technology) filming-type airblast atomizing process

JAXA Supercomputer System Annual Report April 2017-March 2018

Report Number: R17ETET03

Subject Category: Skills Acquisition System

- Responsible Representative: Toshiya Nakamura, Aeronautical Technology Directorate, Next Generation Aeronautical Innovation Hub Center

- Contact Information: Kazuaki Matsuura matsuura.kazuaki@jaxa.jp

- Members: Kazuaki Matsuura, Mitsumasa Makida, Naoki Nakamura, Jun Iino, Huilai Zhang, Shunya Uesaka, Tomoyuki Iwasaki, Ryuta Shinohara, Kazuki Toukaishi

Abstract

Experimental study of planner filming-type airblast atomizer shows the clear effects of the ambient pressure and the vane angles on atomization characteristics. Since the atomization process occurs in the narrow region which is vicinity of the injection outlet, it is difficult to understand the atomization phenomena only by experiment. The objective of this work is to understand the atomization mechanism by numerical study which calculate the atomization field in the near region of the injection outlet.

Reference URL

N/A

Reasons for using JSS2

The particle diameter is order of 10 micron in the experiment. In order to calculate this size of atomization field precisely, large scale calculation with more than a few of hundred million of cells which size is a few micron meter order is needed and the use of super computer is necessary.

Achievements of the Year

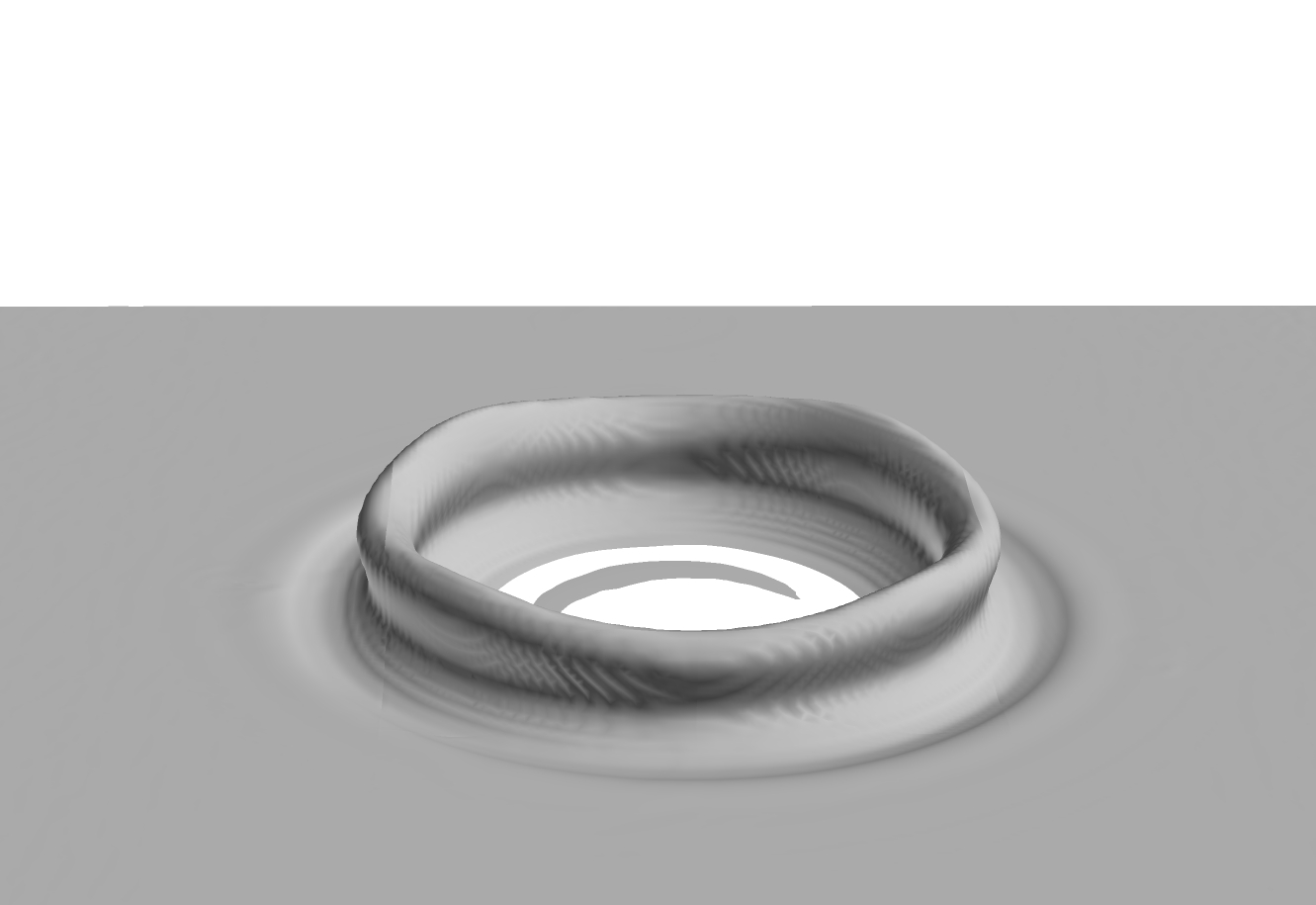

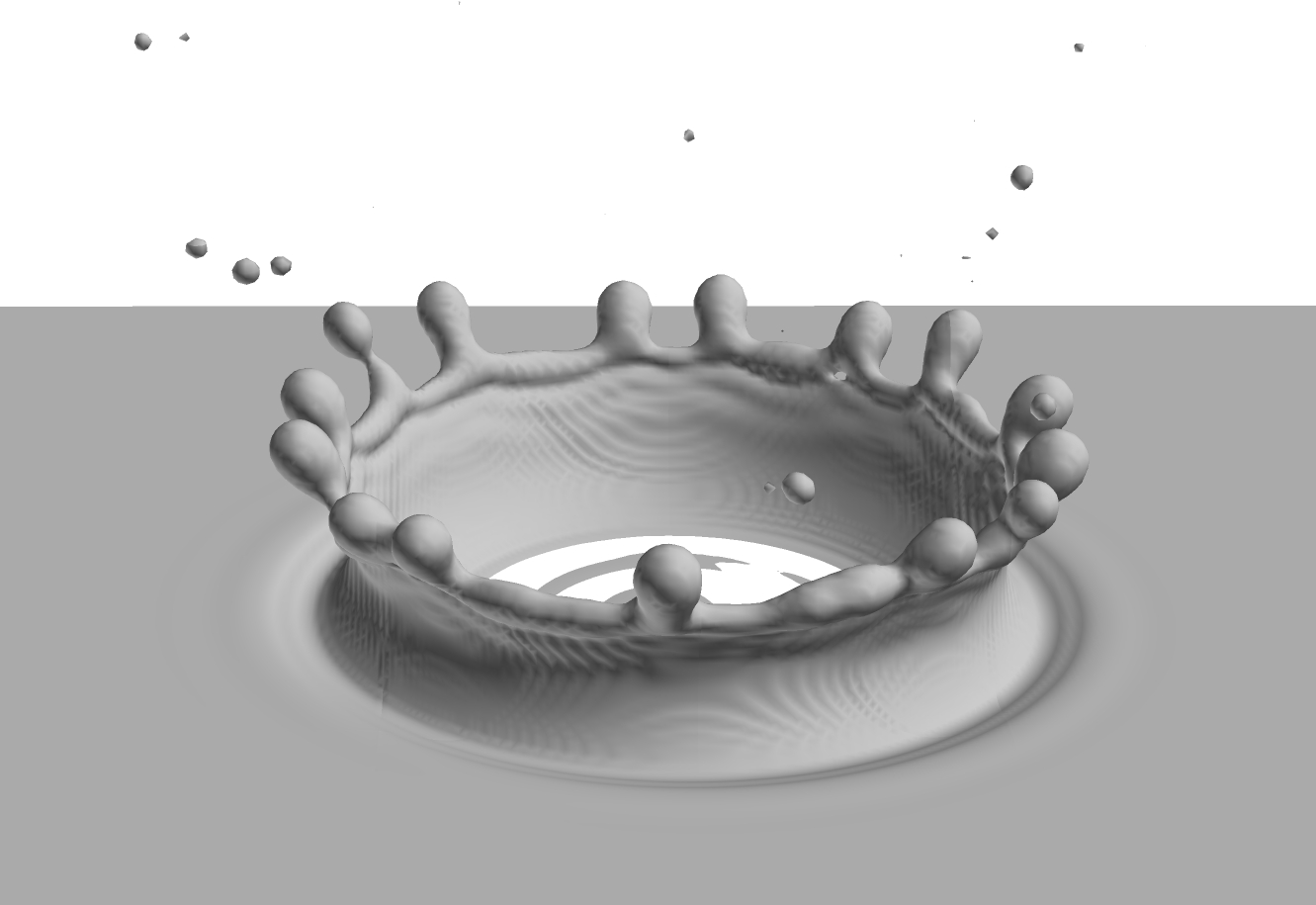

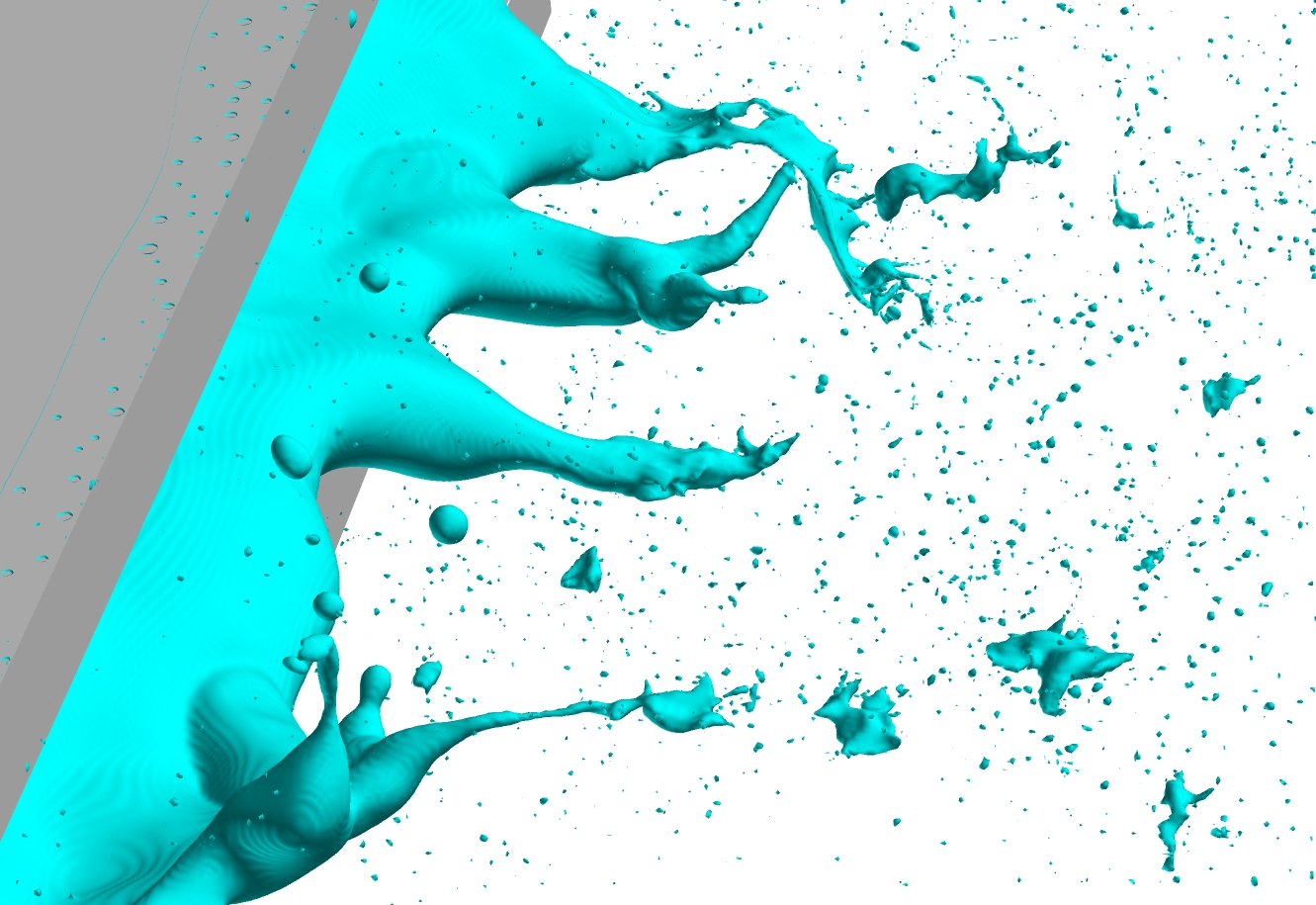

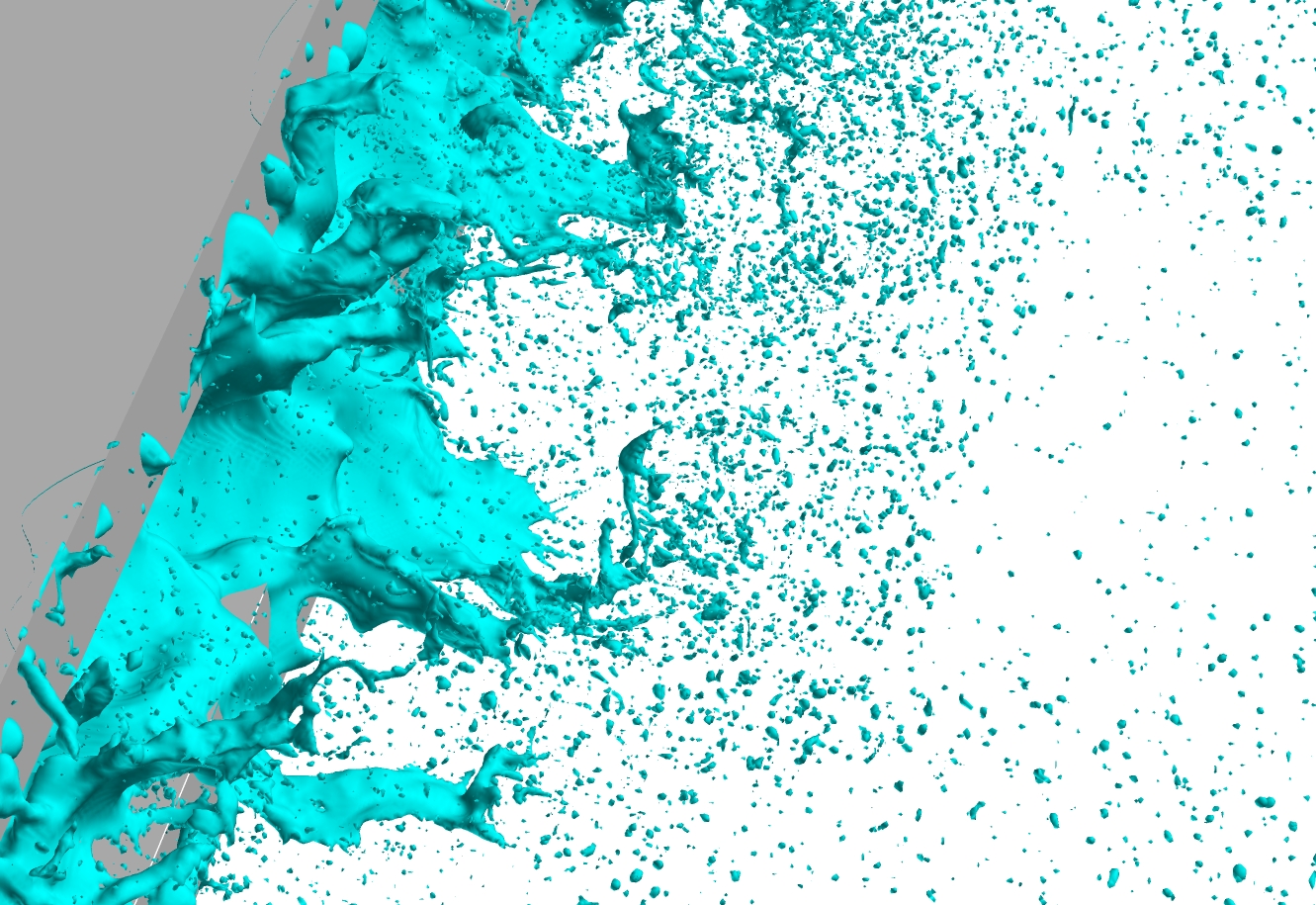

We revised VOF code to reproduce the experimental results of planner filming-type airblast atomizer that the particle diameter with lower ambient pressure becomes larger. We conducted the numerical simulation of milk crown as benchmark test (Fig.1,2). It was confirmed that the revised code reproduce instability needed to form a crown. In the numerical analysis by the revised code for planner filming-type airblast atomizer (Fig.3,4), it was shown that large droplets are divided from ligament, and we came to be able to understand detailed mechanism of break-up which is difficult in the experiment.

Publications

N/A

Usage of JSS2

Computational Information

- Process Parallelization Methods: MPI

- Thread Parallelization Methods: OpenMP

- Number of Processes: 96 – 768

- Elapsed Time per Case: 600.00 hours

Resources Used

Fraction of Usage in Total Resources*1(%): 0.53

Details

Please refer to System Configuration of JSS2 for the system configuration and major specifications of JSS2.

| System Name | Amount of Core Time(core x hours) | Fraction of Usage*2(%) |

|---|---|---|

| SORA-MA | 4,123,371.56 | 0.55 |

| SORA-PP | 1,243.18 | 0.02 |

| SORA-LM | 0.00 | 0.00 |

| SORA-TPP | 0.00 | 0.00 |

| File System Name | Storage Assigned(GiB) | Fraction of Usage*2(%) |

|---|---|---|

| /home | 168.11 | 0.12 |

| /data | 42,757.27 | 0.79 |

| /ltmp | 14,865.46 | 1.12 |

| Archiver Name | Storage Used(TiB) | Fraction of Usage*2(%) |

|---|---|---|

| J-SPACE | 0.14 | 0.01 |

*1: Fraction of Usage in Total Resources: Weighted average of three resource types (Computing, File System, and Archiver).

*2: Fraction of Usage:Percentage of usage relative to each resource used in one year.

JAXA Supercomputer System Annual Report April 2017-March 2018