Internal flow, combustion, and rotating machinery

JAXA Supercomputer System Annual Report April 2017-March 2018

Report Number: R17EG3212

Subject Category: Research and Development

- Responsible Representative: Eiji Shima, Research and Development Directorate, Research Unit III

- Contact Information: Taro Shimizu shimizu.taro@jaxa.jp

- Members: Hiroaki Amakawa, Takayuki Ito, Ryoji Takaki, Seiji Tsutsumi, Hiroyuki Ito, Taro Shimizu, Junya Aono, Takanori Haga, Yuhi Morii, Masaharu Abe, Masayuki Kakehi, Mikiroh Motoe, Manabu Hisida, Hideyo Negishi, Yoichi Ohnishi, Miki Nishimoto, Yu Daimon, Ashvin Hosangadi, Masaaki Ino, Osamu Fukasawa, Shinji Ohno, Andrea Zambon, Takenori Nakajima, Yuka Akimura, Takashi Amemiya, Hironori Fujiwara, Hiroumi Tani, Takuya Iimura, Keiichiro Fujimoto, Tetsufumi Ohmaru, Akiko Kotani, Taroh Fukuda, Mayu Matsumoto, Masashi Toyama, Katsuyuki Ishibashi, Kei Nishimura, Satoshi Abe, Daiki Muto, Nozomu Kanno

Abstract

To capture the unsteady phenomena in the liquid rocket engine, combustion large eddy simulations (LES) are carried out, and this evaluation tool is validated by comparing with a sub-scale test. For thrusters, we build analysis code that can simulate spray combustion mode, first aim at prediction of steady state performance.

Reference URL

Please refer to ‘Research on software, computational engineering, and verification technology | JAXA|Research and Development Directorate‘.

Reasons for using JSS2

Since the flow and combustion in rocket chambers are in a turbulent state and have nonstationary characteristics, LES analysis is essential. Even in this verification target, analysis calculation of about several million steps is required for grid of tens of millions of cells, so it is impossible to achieve the target without using supercomputer.

Achievements of the Year

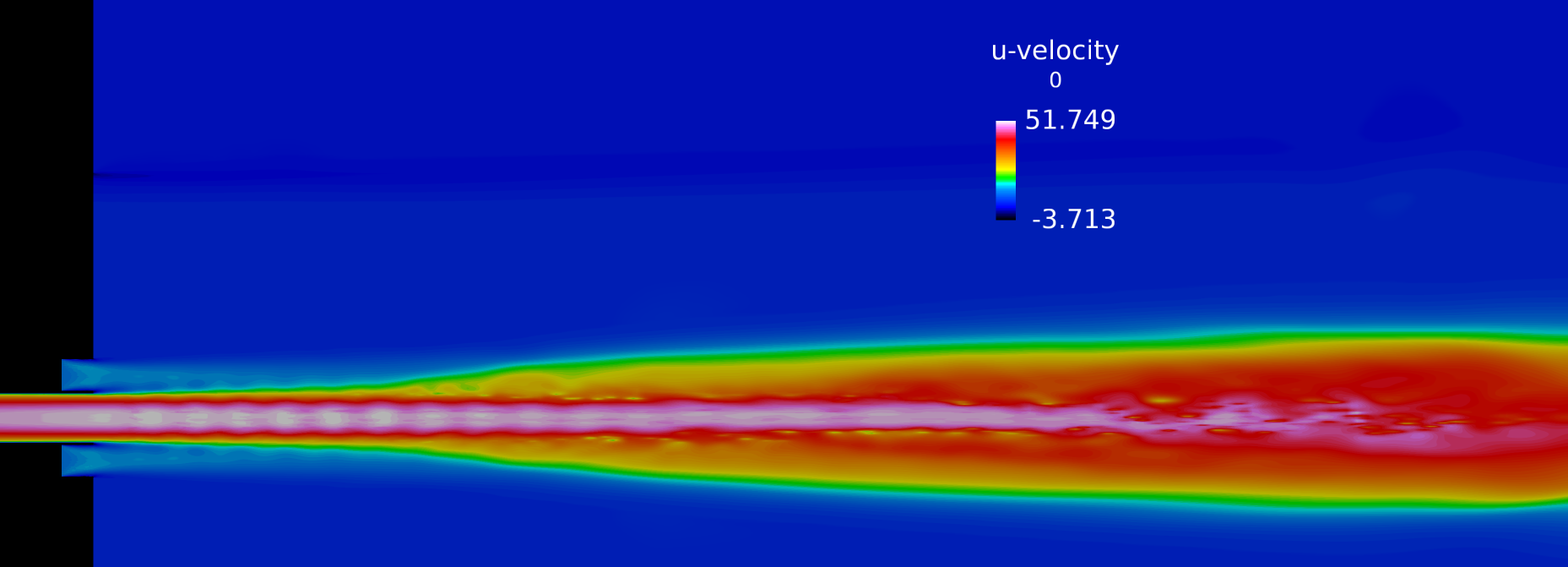

1. In order to develop and validate numerical analysis code for spray combustion, LES of an ethanol spray combustion burner have been conducted. The diameter of target burner is 10.5 mm, and the number of cells of the 3D numerical model is about 15 million. The space has been discretized by finite volume method. Detailed chemical reaction mechanism constructed with 50 species and 258 reactions has been solved to simulate combustion of ethanol, then ERENA method has been use for temporal integration of reactions. Figure 1 and 2 show temperature distribution and axial velocity distribution respectively. As shown in the figures, it is confirmed that the numerical code can reproduce spray combustion qualitatively.

2. Accurate prediction of wall heat flux in combustion chambers using numerical simulations is required for engine designs to prevent the serious damage on the chamber wall due to high heat load. Towards the wall heat flux prediction using LES, wall-modeled LES (WMLES) of turbulent channel flows with heat transfer was performed (Fig. 3). WMLES well predicted velocity and temperature fields in a wide range of Reynolds numbers up to 100,000 in spite of using a coarser grid resolution compared with conventional LES.

Fig.3: WMLES of turbulent channel flow with heat transfer. Iso-surface of velocity colored by temperature is shown.

Publications

■ Presentations

1)Motoe, M., “Combustion Simulation for Coaxial Spray Burner Using Detailed Chemical Reaction Mechanism”, The Japan Society of Fluid Mechanics Annual Meeting 2017 (in Japanese).

2)Muto, D., et al., “Preliminary Study on Wall-modeled Large Eddy Simulation of Turbulent Heat Transfer for Liquid Rocket Engines”, 7th European Conference for Aeronautics and Space Sciences, 649, Jul., 2017.

3) Negishi, H., et al., “Numerical Anaylsis of Unshrouded Impeller Flowfield in the LE-X Liquid Hydrogen Pump”, 53rd AIAA/SAE/ASEE Joint Propulsion Conference, AIAA paper 2017-4930, 2017.

4)Amakawa, H., et al., “Preliminary Study of Numerical Simulation of Macro-Scale Grease Flow Using Moving Particle Simulation -Validation between Experiment and CFD for Grease Dam Break -“, Tribology Comference 2018 Autumn, 2017 (in Japanese).

5) Negishi, H., et al., “Future Perspectives for Grease Flow Simulation in Ball Bearings to enhance Spacecraft Lifetime”, 31st CFD Symposium, E10-3, 2017 (in Japanese).

6) Daimon, Y., et al., “Heat Flux Estimation on a Chamber Wall of GH2/GOX and GCH4/GOX Single Element Rocket Combustors”, 31st International Symposium on Space Technology and Science, 2017.

7) Daimon, Y., et al., “Numerical Investigation on Effects of Recess Variation upon a GCH4/GOX Shear Coaxial Combustion Chamber”, 31st International Symposium on Space Technology and Science, 2017.

8) Daimon, Y., et al., “Film Cooling Performance Analysis of a Full-scale Liquid Rocket Engine Combustion Chamber based on a Coupled Combustion and Heat Transfer Simulation”, AIAA Paper, 2017-4919, 2017.

9) Daimon, Y., et al., “Combustion Modeling Study for a GOX-GCH4 Multi-element Combustion Chamber”, Proceedings of the 2017 Summer Program, SFB TRR40, 2017.

10) Shimizu, T., et al., “Evaluation of the Characteristics of Liquid Hydrogen Mixer using LES”, 31st CFD Symposium, E10-2, 2017 (in Japanese).

■ Invited lecture

1) Negishi, H., “Numerical Modeling of Liquid Rocket Turbopumps”, The National DFG SFB TRR40 project, Graduate Program on Launchers and Propulsion, University of Stuttgart, 2018.

2) Daimon, Y., “Numerical and Experimental Study on Small Thruster”, The National DFG SFB TRR40 project, Graduate Program on Launchers and Propulsion, University of Stuttgart, 2018.

3) Daimon, Y., “GCH4/GO2 Rocket Combustor Simulation -Methane vs Hydrogen, Single vs Multi Element-“, DLR Institute of Combustion Technology Seminar, 2018.

Usage of JSS2

Computational Information

- Process Parallelization Methods: MPI

- Thread Parallelization Methods: N/A

- Number of Processes: 1280 – 2560

- Elapsed Time per Case: 500.00 hours

Resources Used

Fraction of Usage in Total Resources*1(%): 6.10

Details

Please refer to System Configuration of JSS2 for the system configuration and major specifications of JSS2.

| System Name | Amount of Core Time(core x hours) | Fraction of Usage*2(%) |

|---|---|---|

| SORA-MA | 49,901,475.03 | 6.57 |

| SORA-PP | 88,645.47 | 1.11 |

| SORA-LM | 709.56 | 0.37 |

| SORA-TPP | 85,997.68 | 9.60 |

| File System Name | Storage Assigned(GiB) | Fraction of Usage*2(%) |

|---|---|---|

| /home | 6,431.26 | 4.46 |

| /data | 107,461.81 | 1.99 |

| /ltmp | 18,249.37 | 1.38 |

| Archiver Name | Storage Used(TiB) | Fraction of Usage*2(%) |

|---|---|---|

| J-SPACE | 122.73 | 5.28 |

*1: Fraction of Usage in Total Resources: Weighted average of three resource types (Computing, File System, and Archiver).

*2: Fraction of Usage:Percentage of usage relative to each resource used in one year.

JAXA Supercomputer System Annual Report April 2017-March 2018