Study of Green engine (study of ultrahigh-temperature low NOx emission combustor technology) atomization process of a fuel spray nozzle in a practical geometry

JAXA Supercomputer System Annual Report April 2016-March 2017

Report Number: R16E0006

- Responsible Representative: Toshiya Nakamura(Aeronautical Technology Directorate, Next Generation Aeronautical Innovation Hub Center)

- Contact Information: Kazuaki Matsuura(matsuura.kazuaki@jaxa.jp)

- Members: Kazuaki Matsuura, Mitsumasa Makida, Hideshi Yamada, Yoji Kurosawa, Naoki Nakamura, Jun Iino, Huilai Zhang

- Subject Category: Aviation(Aircraft engine)

Abstract

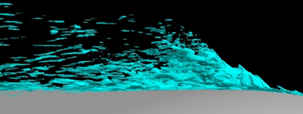

Since the atomization process occurs in the narrow region which is vicinity of the injection outlet in a practical geometry fuel injector, it is difficult to understand the atomization phenomena only by experiment. The objective of this work is to understand the atomization mechanism by numerical study which calculated the atomization field in the near region of the injection outlet.

Goal

In order to promote the efficiency of the combustor development process, numerical analysis of atomization phenomena in a practical geometry which is used in a combustor of Green engine project is conducted.

Objective

The target of this study is to acquire knowledge from series of CFD calculations for constructing CFD technology which can be applied to a development of aircraft engine combustor.

References and Links

N/A

Use of the Supercomputer

To conduct the parametric analysis of large scale, complex fuel atomization field, which concerns the practical geometry precisely, in the short term, the super computer is used practically.

Necessity of the Supercomputer

The particle diameter is order of 10μm in the experiment. In order to calculate this size of atomization field precisely, large scale calculation with more than a few of hundred million of cells which size is a few micron meter order is needed and the use of super computer is necessary.

Achievements of the Year

Numerical analysis with VOF method of the fuel atomization field is conducted and revealed the condition of the particles broken up from cross-flow jet.

Publications

N/A

Computational Information

- Parallelization Methods: Process Parallelization

- Process Parallelization Methods: MPI

- Thread Parallelization Methods: n/a

- Number of Processes: 1024

- Number of Threads per Process: 1

- Number of Nodes Used: 32

- Elapsed Time per Case (Hours): 600

- Number of Cases: 7

Resources Used

Total Amount of Virtual Cost(Yen): 345,879

Breakdown List by Resources

| System Name | Amount of Core Time(core x hours) | Virtual Cost(Yen) |

|---|---|---|

| SORA-MA | 0.12 | 0 |

| SORA-PP | 0.00 | 0 |

| SORA-LM | 0.00 | 0 |

| SORA-TPP | 0.00 | 0 |

| File System Name | Storage assigned(GiB) | Virtual Cost(Yen) |

|---|---|---|

| /home | 45.60 | 430 |

| /data | 31,459.46 | 296,758 |

| /ltmp | 5,161.83 | 48,691 |

| Archiving System Name | Storage used(TiB) | Virtual Cost(Yen) |

|---|---|---|

| J-SPACE | 0.00 | 0 |

Note: Virtual Cost=amount of cost, using the unit price list of JAXA Facility Utilization program(2016)

JAXA Supercomputer System Annual Report April 2016-March 2017