Environment Conscious Aircraft Systems Research in Eco-wing Technology:Aerodynamic System Design Technology

JAXA Supercomputer System Annual Report April 2016-March 2017

Report Number: R16E0001

- Responsible Representative: Yoshikazu Makino(Next Generation Aeronautical Innovation Hub Center, Aeronautical Technology Directorate)

- Contact Information: Dongyoun Kwak(kwak.dongyoun@jaxa.jp)

- Members: Soichiro Tabata, Yoshihisa Aoki, Wataru Yamazaki, Mitsuhiro Murayama, Dongyoun Kwak, Naoko Tokugawa, Kie Okabayashi, Takashi Atobe, Tatsunori Yuhara, Fumitake Kuroda, Yoshine Ueda, Keisuke Ohira, Hikaru Aono, Kisa Matsushima, Satoshi Kondo, Tohru Hirai, Kentaro Tanaka, Takashi Matsuno, Shunsuke Imai, Sasamori Monami, Shinsuke Nishimura, Minoru Yoshimoto

- Subject Category: Aviation(Aircraft,Body structure)

Abstract

Innovative drag reduction technologies are investigated to reduce the fuel consumption for a conventional aircraft configuration. Aircraft noise prediction technologies and the conceptual design technologies are also developed for future aircraft which achieve low noise and high efficiency.

Goal

Please refer ‘Eco-wing technology | ECAT – Environment-Conscious Aircraft Technology Program | Aeronautical Technology Directorate‘.

Objective

Please refer ‘Eco-wing technology | ECAT – Environment-Conscious Aircraft Technology Program | Aeronautical Technology Directorate‘.

References and Links

Please refer ‘Eco-wing technology | ECAT – Environment-Conscious Aircraft Technology Program | Aeronautical Technology Directorate‘.

Use of the Supercomputer

CFD analysis are used for the understanding of aerodynamic characteristics and evaluation of the performance in the aircraft design phase.

Necessity of the Supercomputer

Huge calculation resources and costs were required for the high fidelity and quick response CFD analysis for the optimum aerodynamic design process on complex aircraft geometry. JSS2 can achieve those requirements, the cost and time are drastically saved on the CFD analysis.

Achievements of the Year

Drag reduction technologies are investigated to reduce the fuel consumption for a for a conventional aircraft configuration (TRA2022).

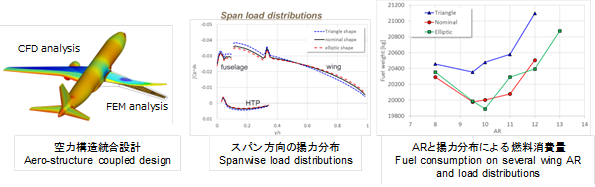

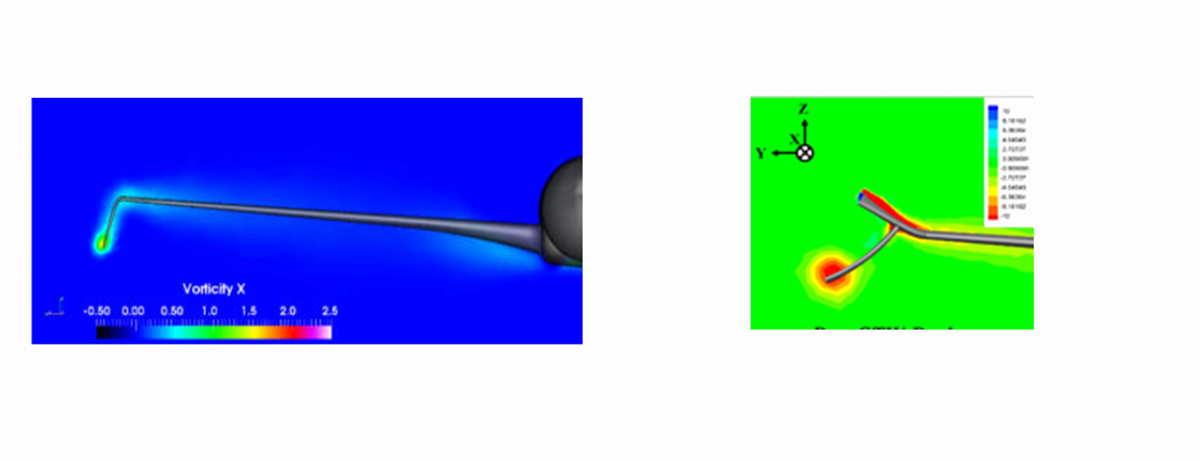

Aerodynamic and structure coupled design were performed based on TRA2012A(Technology reference aircraft), fuel consumption rates were evaluated on several wing aspect ratios and span load distributions. Design knowledges were obtained for low drag wing with higher aspect ratio on TRA2022. Aerodynamic design of wingtip devices was also conducted for enhanced performance of a transonic aircraft. We obtained promising shapes: downward-point rakelet and split tip winglet (Fig.2).

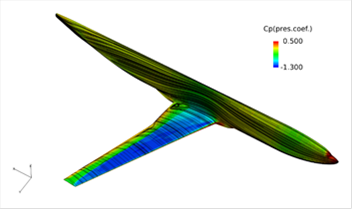

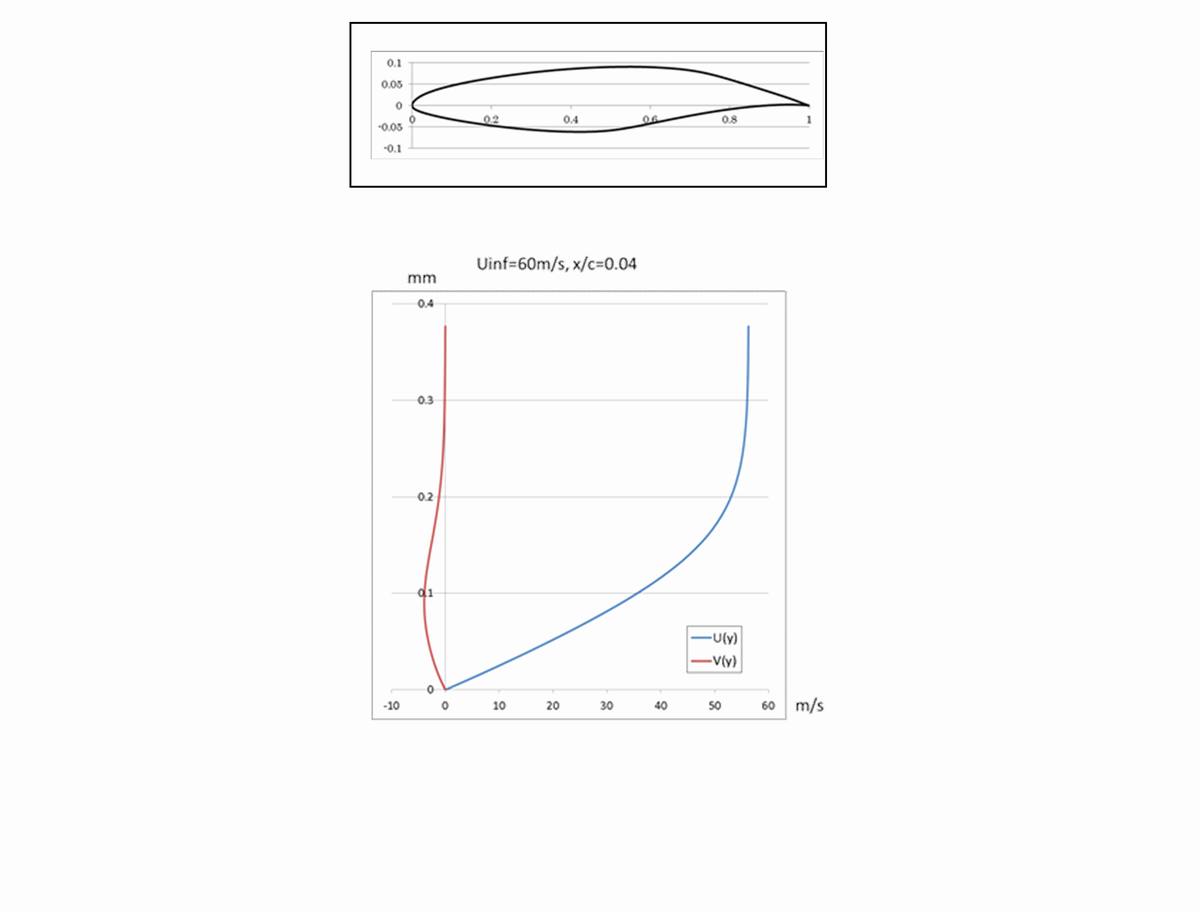

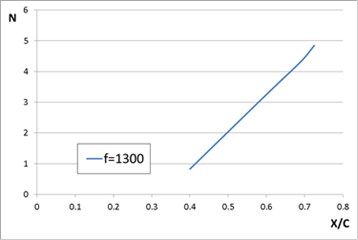

Research for boundary layer transition control also performed to reduce the friction drag. Natural laminar flow wing was designed for TRA2012A. Since CFD solver was replaced from UPACS to FaSTAR, the efficiency of design was improved. As results, the natural laminar flow design was achieved within about 30 design cycles and drag reduction of about 3.7 cts. was obtained(Fig.3). Research for transition control of the boundary layer by use of the DBD Plasma actuator to reduce the friction drag of a wing. Fig.4 shows the airfoil and the velocity profile at x/c=0.04. U corresponds to the velocity component in external flow, and V in the normal to U. Fig.5 shows the result of the linear stability analysis using the velocity profiles. It is shown that the transition might be occur at nearly x/c=0/7, and the frequency of disturbance is around 10kHz. These results will be used to development of the numerical analysis scheme using the plasma actuator.

Publications

Presentations

1) Oda, Y., Yuhara, T. and Rinoie, K., Studies on Wingtip Geometries by Optimum span wise Lift Distribution Design Method, The 55th AIAA Aerospace Sciences Meeting, 2017.

2) Dongyoun Kwak, Toshiyuki Nomura, Naoko Tokugawa, Mitsuru Kurita, Mitsuhiro Murayama, Introduction of research project for environmental conscious aircraft technology in JAXA, Greener Aviation 2016 Symposium, Brussels, Belgium, Oct., 2016.

3) Dongyoun Kwak, Hotoshi Arizono, Toshiyuki Nomura, Studies on the lift distribution and aspect ratio for the fuel consumption reduction onsubsonic aircraft, 2016 Asia-Pacific International Symposium on Aerospace Technology, Toyama, Japan, Oct., 2016.

Computational Information

- Parallelization Methods: Process Parallelization, Thread Parallelization, Hybrid Parallelization, Serial

- Process Parallelization Methods: MPI

- Thread Parallelization Methods: OpenMP , Automatic Parallelization

- Number of Processes: 15-300

- Number of Threads per Process: 4-32

- Number of Nodes Used: 1-32

- Elapsed Time per Case (Hours): 0.5-5

- Number of Cases: 3000

Resources Used

Total Amount of Virtual Cost(Yen): 12,713,115

Breakdown List by Resources

| System Name | Amount of Core Time(core x hours) | Virtual Cost(Yen) |

|---|---|---|

| SORA-MA | 7,131,132.15 | 11,662,448 |

| SORA-PP | 77,179.78 | 658,961 |

| SORA-LM | 65.33 | 1,470 |

| SORA-TPP | 0.00 | 0 |

| File System Name | Storage assigned(GiB) | Virtual Cost(Yen) |

|---|---|---|

| /home | 331.18 | 3,124 |

| /data | 21,455.68 | 202,392 |

| /ltmp | 17,547.91 | 165,529 |

| Archiving System Name | Storage used(TiB) | Virtual Cost(Yen) |

|---|---|---|

| J-SPACE | 6.22 | 19,190 |

Note: Virtual Cost=amount of cost, using the unit price list of JAXA Facility Utilization program(2016)

JAXA Supercomputer System Annual Report April 2016-March 2017