Research on Structure and Composite Material Technologies for Digital Certification

JAXA Supercomputer System Annual Report February 2024-January 2025

Report Number: R24EA1601

Subject Category: Aeronautical Technology

- Responsible Representative: Tomo Takeda, Aviation Technology Directorate, Aircraft Digital Transformation Technology Demonstration Project Team

- Contact Information: Tomo Takeda(takeda.tomo@jaxa.jp)

- Members: Yasutomo Tateishi, Hikaru Hoshi, Yuichiro Aoki, Sunao Sugimoto, Toshiya Nakamura

Abstract

The objective of this research is to develop a simplified finite element modeling methodology to predict the thermal deformation of carbon fiber reinforced polymer (CFRP) laminates during their automated fiber placement (AFP) manufacturing process.

Reference URL

N/A

Reasons and benefits of using JAXA Supercomputer System

High-performance parallel computing is necessary because the numerical model is computationally expensive.

Achievements of the Year

A simplified finite element modeling methodology was developed to predict the thermal deformation of carbon fiber reinforced polymer (CFRP) laminates during their automated fiber placement (AFP) manufacturing process. The obtained results are as follows.

(1) The finite element model predicts the thermal deformation of CFRP laminates by taking account of the temperature difference between prepreg layers from a thermal analysis. In this model, the thermal deformation states of pre-placed layers are used as initial conditions.

(2) The modeling process is automated to achieve savings in the modeling time.

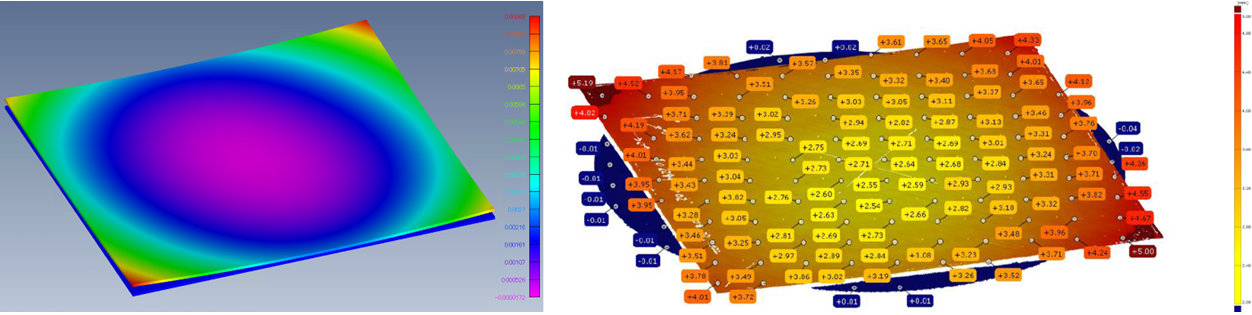

(3) The predicted deformation states were in qualitative agreement with the experimental result (Fig. 1).

(4) Based on the results of the prediction accuracy and computational time, it was found that the finite element model is effective for predictig the thermal deformation of CFRP laminates.

Publications

- Oral Presentations

Yasutomo Tateishi, Yoshiaki Yamaoka, Hikaru Hoshi, Yuichiro Aoki, Sunao Sugimoto, Toshiya Nakamura, Study of finite element thermal modeling of thermoplastic composite laminates for ISC process by AFP , 66th JSASS/JSME/JAXA Structures Conference, Tosu, August 2024.

Usage of JSS

Computational Information

- Process Parallelization Methods: MPI

- Thread Parallelization Methods: OpenMP

- Number of Processes: 2 - 256

- Elapsed Time per Case: 86400 Second(s)

JSS3 Resources Used

Fraction of Usage in Total Resources*1(%): 0.01

Details

Please refer to System Configuration of JSS3 for the system configuration and major specifications of JSS3.

| System Name | CPU Resources Used(Core x Hours) | Fraction of Usage*2(%) |

|---|---|---|

| TOKI-SORA | 0.00 | 0.00 |

| TOKI-ST | 11.64 | 0.00 |

| TOKI-GP | 0.00 | 0.00 |

| TOKI-XM | 0.00 | 0.00 |

| TOKI-LM | 0.00 | 0.00 |

| TOKI-TST | 0.00 | 0.00 |

| TOKI-TGP | 0.00 | 0.00 |

| TOKI-TLM | 0.00 | 0.00 |

| File System Name | Storage Assigned(GiB) | Fraction of Usage*2(%) |

|---|---|---|

| /home | 248.71 | 0.17 |

| /data and /data2 | 74342.09 | 0.36 |

| /ssd | 0.00 | 0.00 |

| Archiver Name | Storage Used(TiB) | Fraction of Usage*2(%) |

|---|---|---|

| J-SPACE | 0.00 | 0.00 |

*1: Fraction of Usage in Total Resources: Weighted average of three resource types (Computing, File System, and Archiver).

*2: Fraction of Usage:Percentage of usage relative to each resource used in one year.

ISV Software Licenses Used

| ISV Software Licenses Used(Hours) | Fraction of Usage*2(%) | |

|---|---|---|

| ISV Software Licenses(Total) | 0.00 | 0.00 |

*2: Fraction of Usage:Percentage of usage relative to each resource used in one year.

JAXA Supercomputer System Annual Report February 2024-January 2025