Application of distributed micro plasma actuators

JAXA Supercomputer System Annual Report February 2024-January 2025

Report Number: R24EACA47

Subject Category: JSS Inter-University Research

- Responsible Representative: Takashi Matsuno, Associate Professor, Tottori University

- Contact Information: Takashi Matsuno(matsuno@tottori-u.ac.jp)

- Members: Masahiro Kanazaki, Taiki Kato, Seiichiro Morizawa, Takashi Matsuno, Takumi Nakagawa

Abstract

Plasma actuators (PAs) are flow control devices that use discharged plasma to generate wall jets from smooth surfaces. In recent years, a method of generating a distribution of body force on a surface by using a large number of small-scale PAs has been proposed by the applicants. The objective of this study is to obtain knowledge about the application method of plasma actuator and its optimization method for arbitrary control of the velocity profile of a three-dimensional boundary layer, keeping in mind the boundary layer control of high-speed flows.

Reference URL

N/A

Reasons and benefits of using JAXA Supercomputer System

In order to perform large-scale 3D flow analysis and aerodynamic optimization with high computational costs, a supercomputer is required. The JAXA supercomputer, which provides an environment for the use of computational tools, is the most suitable environment for this study.

Achievements of the Year

This year, we expanded the application range of the optimal design methodology developed in the previous year and verified its applicability to practical problems. Initially, the plan was to optimize plasma actuators (PA) for boundary layer control on swept wings; however, due to the time required for examining the implementation method of PA within the optimization process, we instead focused on bluff body problems, which exhibit pronounced flow variations, straightforward solution exploration, and higher degrees of freedom in design variables, to validate the design methodology.

Optimal designs were conducted for both two-dimensional and three-dimensional configurations, defining the shapes of flow control devices attached to bluff bodies as free-form surfaces using NURBS with up to 24 design variables to solve the drag minimization problem. For the three-dimensional computations, numerical grids consisting of approximately 20 million points were generated using Pointwise, and flow analysis was carried out with FaSTAR utilizing Reynolds-averaged Navier-Stokes (RANS) equations. The optimal design was performed using EGO and EGO-MAs, with design spaces narrowed based on the feature extraction results from the previous year. In two-dimensional analyses, optimal designs were conducted under various conditions by altering the design domain of the flow control devices to investigate their performance dependency on the design domain. These findings demonstrated that the developed methodology efficiently facilitates aerodynamic optimization of complex shapes.

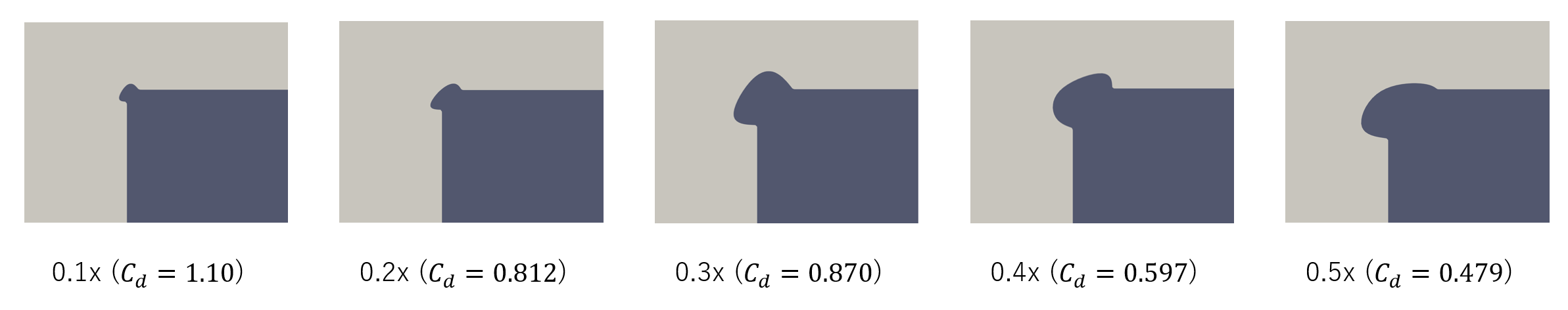

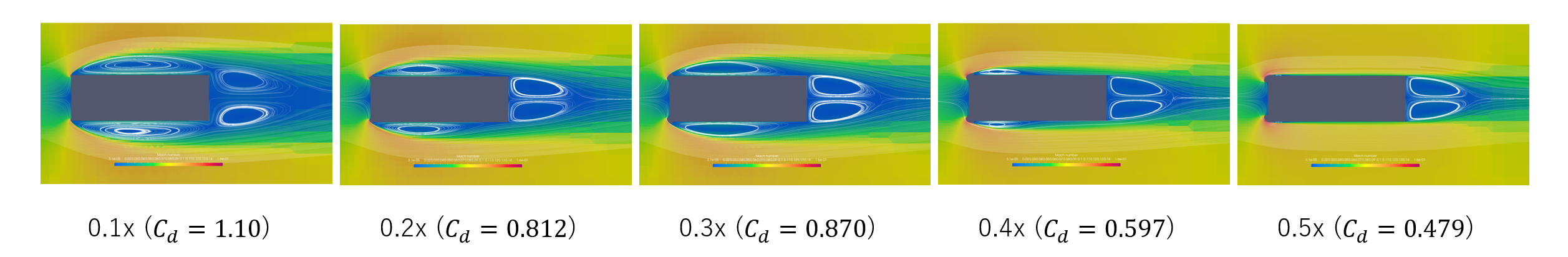

Figure 1 shows examples of flow control device shapes achieving minimum drag obtained from two-dimensional optimal designs. The terms 0.1x – 0.5x indicate the scale reduction ratios relative to the reference domain size, where, for instance, the 0.1x scale corresponds to a maximum fairing width of 3% of the total width. Figure 2 displays Mach number distributions and streamlines around bluff bodies equipped with these corresponding flow control devices. The knowledge obtained regarding the minimal device size required to achieve drag reduction through separation control and the shape characteristics for each size were leveraged in the three-dimensional design process. This problem was identified as suitable for validating optimal design methods and will continue to be utilized in future studies. Furthermore, building upon insights gained from this research, we aim to propose and optimize novel flow control concepts that combine plasma actuators with flow control devices, validating them through wind tunnel experiments.

Fig.1: Examples of flow control device shapes achieving minimum drag obtained from two-dimensional optimal designs

Fig.2: Mach number distributions and streamlines around bluff bodies equipped with these corresponding flow control devices

Publications

- Oral Presentations

T. Nakagawa, S. Ito, K. Tomokawa, and T. Matsuno, "Design Exploration of a Front-Corner Flow Control Device for Suppressing Three-Dimensional Separation on Commercial Vehicles," No.255-1, Tokushima, 2025, 07C3.(in Japanese)

- Poster Presentations

T. Nakagawa,"Optimization of Drag-Reduction Devices Installed on the Front Corner of a Bluff Body Using Numerical Simulation," Aerospace Fluid Dynamics Summer School 2024, Sendai, 2024.(in Japanese)

Usage of JSS

Computational Information

- Process Parallelization Methods: MPI

- Thread Parallelization Methods: N/A

- Number of Processes: 12 - 1000

- Elapsed Time per Case: 8 Hour(s)

JSS3 Resources Used

Fraction of Usage in Total Resources*1(%): 0.02

Details

Please refer to System Configuration of JSS3 for the system configuration and major specifications of JSS3.

| System Name | CPU Resources Used(Core x Hours) | Fraction of Usage*2(%) |

|---|---|---|

| TOKI-SORA | 252399.75 | 0.01 |

| TOKI-ST | 22945.27 | 0.02 |

| TOKI-GP | 0.00 | 0.00 |

| TOKI-XM | 0.00 | 0.00 |

| TOKI-LM | 4075.14 | 0.29 |

| TOKI-TST | 0.00 | 0.00 |

| TOKI-TGP | 0.00 | 0.00 |

| TOKI-TLM | 0.00 | 0.00 |

| File System Name | Storage Assigned(GiB) | Fraction of Usage*2(%) |

|---|---|---|

| /home | 163.33 | 0.11 |

| /data and /data2 | 7963.00 | 0.04 |

| /ssd | 0.00 | 0.00 |

| Archiver Name | Storage Used(TiB) | Fraction of Usage*2(%) |

|---|---|---|

| J-SPACE | 0.00 | 0.00 |

*1: Fraction of Usage in Total Resources: Weighted average of three resource types (Computing, File System, and Archiver).

*2: Fraction of Usage:Percentage of usage relative to each resource used in one year.

ISV Software Licenses Used

| ISV Software Licenses Used(Hours) | Fraction of Usage*2(%) | |

|---|---|---|

| ISV Software Licenses(Total) | 390.12 | 0.27 |

*2: Fraction of Usage:Percentage of usage relative to each resource used in one year.

JAXA Supercomputer System Annual Report February 2024-January 2025